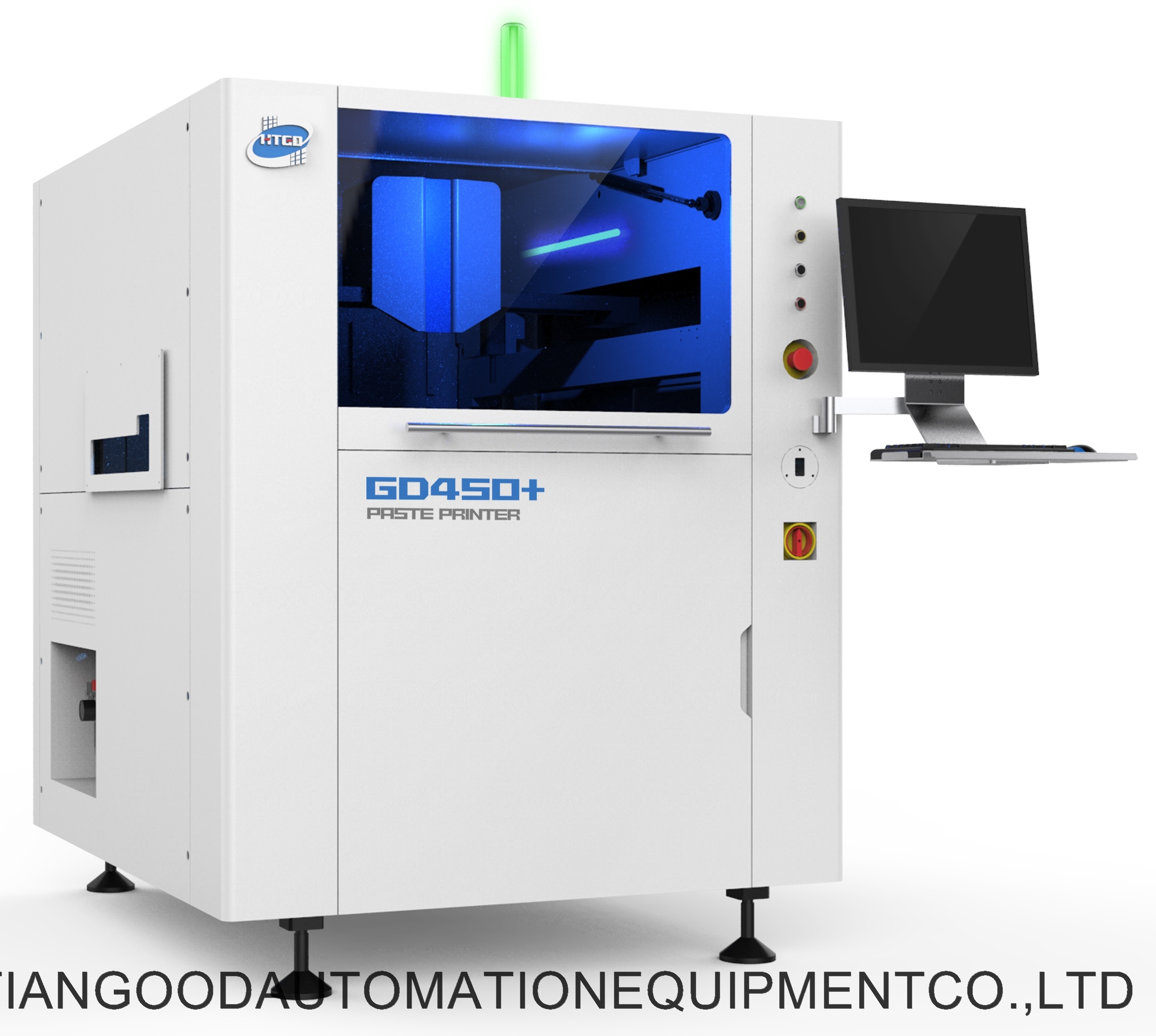

Solder paste printing press

Solder paste printing press

MOQ :1 set

Lead Time :30 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Western Union, Money Gram, Credit Card, Paypal

Product details

Supply Ability

- Supply Ability:100 piecesWarranty(Year):1 Year

Packaging & Delivery

- Length:114 cmWidth:140 cm

- Height:148 cmLogistics Weight:1000.000 kg/set

- Packaging:1 set

Product Specifications

- Brand name:HTGD

Product Description

GD450+? 技术规格 GD450+? Parameters | |

PCB参数 PCB parameters | |

最大板尺寸 (X x Y) Max board size | 450mm x 350mm |

最小板尺寸 (Y x X) Min board size | 50mm x 50mm |

PCB厚度 PCB thickness | 0.4mm~6mm |

翘曲量 Warpage | Max. PCB对角线 1% Max. PCB diagonal 1% |

最大板重量 Max board weight | 6Kg |

板边缘间隙 Board edge spacing | 构形至 3 mm configuration to 3mm |

最大底部间隙 Max bottom spacing | 15mm |

传送速度 Transmission speed | 1500mm/秒(Max) 1500mm/s(Max) |

距地面的传送高度 Transmission height to the land | 900±40mm |

传送轨道方向 Transmission direction | 左 – 右、右 – 左、左 – 左、右 – 右 Left-Right, Right-Left, Left-Left, Right-Right |

传输方式 Transmission method | 一段式运输导轨 One-stage transmission rail |

PCB夹持方法 PCB pick-up method | 软件可调压力的弹性侧压(选配: 底部多点或局部真空或整体吸腔式真空) Software can change the elastic lateral pressure(Optional: multipoint on the bottom or partial vacuum or whole vacuum). |

板支撑方法 Board supporting method | 磁性顶针,等高块,专用的工件夹具 Magnetic thimble, contour blocks, special workpiece fixture |

印刷参数Printing parameters | |

印刷头 Printing head | 两个独立直联的马达驱动 Two independent straight league motor drives |

模板框架尺寸 Template frame size | 370mm x 470mm(470左右放置)~737 mm x 737 mm 370mm x 470mm(470 left/right placed)~737 mm x 737 mm |

最大印刷区域 (X x Y) Max printing area | 450mm x 350mm |

刮刀类型 Scraper type | 钢刮刀/胶刮刀(角度45°/55°/60°按印刷工艺匹配选择) Stencil scraper/rubber scraper(angle 45°/55°/60° select according to the printing technology) |

印刷模式 Printing mode | 单或双刮刀印刷 Single or two scrapers printing |

脱模长度 Demoulding length | 0.02 mm 至 12 mm 0.02 mm to 12 mm |

印刷速度 Printing speed | 6 mm/秒至 200 mm/秒 6 mm/s to 200 mm/s |

印刷压力 Printing pressure | 0.5kg 至10Kg 0.5kg to 10Kg |

印刷行程 Printing movement | ±250 mm(从中心) ±250 mm (from the center) |

影像参数 Image parameters | |

影像视域 (FOV) Field of view(FOV) | 6.4mm x 4.8mm |

平台调整范围 Table adjustable area | X,Y:±7.0mm θ:±2.0° |

基准点类型 Reference point type | 标准形状基准点 (见SMEMA 标准),焊盘 /开孔 Standard reference point(see SMEMA standard),bonding pad/hole |

摄像机系统 Camera system | 单独照相机 , 向上 / 向下单独成像视觉系统,几何匹配定位 Individual camera, Up/down individual imaging visual system, geometric matching positioning |

性能参数 Performance parameters | |

影像校准重复精度 Imaging alignment repeated accuracy | ±12.5微米 (±0.0005") @6 σ,Cpk 大于或者等于 2.0 ±12.5μ(±0.0005") @6 σ,Cpk≥2.0 |

印刷重复精度 Printing repeated accuracy | ±25 微米 (±0.001") @6 σ,Cpk 大于或者等于 2.0 ±25μ(±0.001") @6 σ,Cpk ≥ 2.0 |

循环时间 Cycle time | 少于 7.5s Less than 7.5s |

换线时间 Replace line time | 少于5mins Less than 5mins |

设备Equipment | |

功率要求 Power | AC220V±10%,50/60HZ,15A |

压缩空气要求 Compressed air | 4~6Kg/cm2, 10.0 直径管 4~6Kg/cm2, 10.0 tube |

操作系统 Operation system | Windows XP |

设备尺寸 Equipment size | 1140mm(长) x 1400mm(宽) x 1480mm(高)(不包括显示器及三色灯高度)1140mm(L) x 1400mm(W) x 1480mm(H)( Do not include the screen and tri-color light height) |

机器重量 Equipment weight | 约1000Kg About 1000kg |

![]() 1.2.3光学系统(Fiducially mark光学对准标记)Optical system(Fiducially mark optical alignment mark)

1.2.3光学系统(Fiducially mark光学对准标记)Optical system(Fiducially mark optical alignment mark)

标记点探测 Fiducial Mark Detection | 用一个CCD相机通过网板和基板上两个标志点进行识别 Use a CCD camera to detect through the two fiducial marks on the stencil and base board |

调整方式 Alignment Mode | 用相机探测到PCB和网板位置,通过视觉校正系统软件控制万向工作台作X—Y—θ方向修正,实现网板与基板的对准 Use camera to detect the position of PCB and stencil. Correct the X—Y—θdirection of the worktable through the visual alignment system software and insure the alignment of the stencil and base board. |

标记点形状 Fiducial Mark Shape | 任何形状 Any shape |

标记点大小 Fiducial Mark Size | 可做成直径或边长为1mm~2.5mm的各种形状的孔,允许偏差10% Any shape of holes which diameter or length are 1mm~2.5mm. 10% offset allowed. |

标记点类型 Fiducial Mark Type | 透空型:周边用薄铜材料 半透空型:中间为透明或半透明涂层材料可用镍、青铜等 Open type: thin copper material on the surrounding. Half-open type: transparent or semitransparent coating material on the middle. Can be nickel, bronze, etc. |

标记点要求 Fiducial Mark Require | 标志点涂层表面要求平且光滑 Coating surface of the fiducial mark need be even and smooth. |

GD450+? 技术规格 GD450+? Parameters | |

PCB参数 PCB parameters | |

最大板尺寸 (X x Y) Max board size | 450mm x 350mm |

最小板尺寸 (Y x X) Min board size | 50mm x 50mm |

PCB厚度 PCB thickness | 0.4mm~6mm |

翘曲量 Warpage | Max. PCB对角线 1% Max. PCB diagonal 1% |

最大板重量 Max board weight | 6Kg |

板边缘间隙 Board edge spacing | 构形至 3 mm configuration to 3mm |

最大底部间隙 Max bottom spacing | 15mm |

传送速度 Transmission speed | 1500mm/秒(Max) 1500mm/s(Max) |

距地面的传送高度 Transmission height to the land | 900±40mm |

传送轨道方向 Transmission direction | 左 – 右、右 – 左、左 – 左、右 – 右 Left-Right, Right-Left, Left-Left, Right-Right |

传输方式 Transmission method | 一段式运输导轨 One-stage transmission rail |

PCB夹持方法 PCB pick-up method | 软件可调压力的弹性侧压(选配: 底部多点或局部真空或整体吸腔式真空) Software can change the elastic lateral pressure(Optional: multipoint on the bottom or partial vacuum or whole vacuum). |

板支撑方法 Board supporting method | 磁性顶针,等高块,专用的工件夹具 Magnetic thimble, contour blocks, special workpiece fixture |

印刷参数Printing parameters | |

印刷头 Printing head | 两个独立直联的马达驱动 Two independent straight league motor drives |

模板框架尺寸 Template frame size | 370mm x 470mm(470左右放置)~737 mm x 737 mm 370mm x 470mm(470 left/right placed)~737 mm x 737 mm |

最大印刷区域 (X x Y) Max printing area | 450mm x 350mm |

刮刀类型 Scraper type | 钢刮刀/胶刮刀(角度45°/55°/60°按印刷工艺匹配选择) Stencil scraper/rubber scraper(angle 45°/55°/60° select according to the printing technology) |

印刷模式 Printing mode | 单或双刮刀印刷 Single or two scrapers printing |

脱模长度 Demoulding length | 0.02 mm 至 12 mm 0.02 mm to 12 mm |

印刷速度 Printing speed | 6 mm/秒至 200 mm/秒 6 mm/s to 200 mm/s |

印刷压力 Printing pressure | 0.5kg 至10Kg 0.5kg to 10Kg |

印刷行程 Printing movement | ±250 mm(从中心) ±250 mm (from the center) |

影像参数 Image parameters | |

影像视域 (FOV) Field of view(FOV) | 6.4mm x 4.8mm |

平台调整范围 Table adjustable area | X,Y:±7.0mm θ:±2.0° |

基准点类型 Reference point type | 标准形状基准点 (见SMEMA 标准),焊盘 /开孔 Standard reference point(see SMEMA standard),bonding pad/hole |

摄像机系统 Camera system | 单独照相机 , 向上 / 向下单独成像视觉系统,几何匹配定位 Individual camera, Up/down individual imaging visual system, geometric matching positioning |

性能参数 Performance parameters | |

影像校准重复精度 Imaging alignment repeated accuracy | ±12.5微米 (±0.0005") @6 σ,Cpk 大于或者等于 2.0 ±12.5μ(±0.0005") @6 σ,Cpk≥2.0 |

印刷重复精度 Printing repeated accuracy | ±25 微米 (±0.001") @6 σ,Cpk 大于或者等于 2.0 ±25μ(±0.001") @6 σ,Cpk ≥ 2.0 |

循环时间 Cycle time | 少于 7.5s Less than 7.5s |

换线时间 Replace line time | 少于5mins Less than 5mins |

设备Equipment | |

功率要求 Power | AC220V±10%,50/60HZ,15A |

压缩空气要求 Compressed air | 4~6Kg/cm2, 10.0 直径管 4~6Kg/cm2, 10.0 tube |

操作系统 Operation system | Windows XP |

设备尺寸 Equipment size | 1140mm(长) x 1400mm(宽) x 1480mm(高)(不包括显示器及三色灯高度)1140mm(L) x 1400mm(W) x 1480mm(H)( Do not include the screen and tri-color light height) |

机器重量 Equipment weight | 约1000Kg About 1000kg |

![]() 1.2.3光学系统(Fiducially mark光学对准标记)Optical system(Fiducially mark optical alignment mark)

1.2.3光学系统(Fiducially mark光学对准标记)Optical system(Fiducially mark optical alignment mark)

标记点探测 Fiducial Mark Detection | 用一个CCD相机通过网板和基板上两个标志点进行识别 Use a CCD camera to detect through the two fiducial marks on the stencil and base board |

调整方式 Alignment Mode | 用相机探测到PCB和网板位置,通过视觉校正系统软件控制万向工作台作X—Y—θ方向修正,实现网板与基板的对准 Use camera to detect the position of PCB and stencil. Correct the X—Y—θdirection of the worktable through the visual alignment system software and insure the alignment of the stencil and base board. |

标记点形状 Fiducial Mark Shape | 任何形状 Any shape |

标记点大小 Fiducial Mark Size | 可做成直径或边长为1mm~2.5mm的各种形状的孔,允许偏差10% Any shape of holes which diameter or length are 1mm~2.5mm. 10% offset allowed. |

标记点类型 Fiducial Mark Type | 透空型:周边用薄铜材料 半透空型:中间为透明或半透明涂层材料可用镍、青铜等 Open type: thin copper material on the surrounding. Half-open type: transparent or semitransparent coating material on the middle. Can be nickel, bronze, etc. |

标记点要求 Fiducial Mark Require | 标志点涂层表面要求平且光滑 Coating surface of the fiducial mark need be even and smooth. |

You May Like

- Free Member

- Trade Assurance

Company Location: GUANG DONG